|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2330-385-14

This task covers:

a. Removal

c. Installation

b. Cleaning/Inspection

d. Follow-On Maintenance

INITIAL SETUP

Tools and Special Tools

Equipment Condition

Tool Kit, General Mechanic's: Automotive

Wheels chocked, (Para 2-20)

(Item 50, Appendix J)

Flatrack removed, (TM 9-2320-364-10)

Rod, Unlocking (Item 8, Appendix C)

Air system drained, (Para 2-21)

Flatrack lock chamber caged, (Para 4-65)

Material/Parts

Compound, Anti-Seize (Item 5, Appendix E)

Bushing (2) (Item 2, Appendix I)

Pin, Cotter (2) (Item 66, Appendix I)

Pin, Cotter (Item 68, Appendix I)

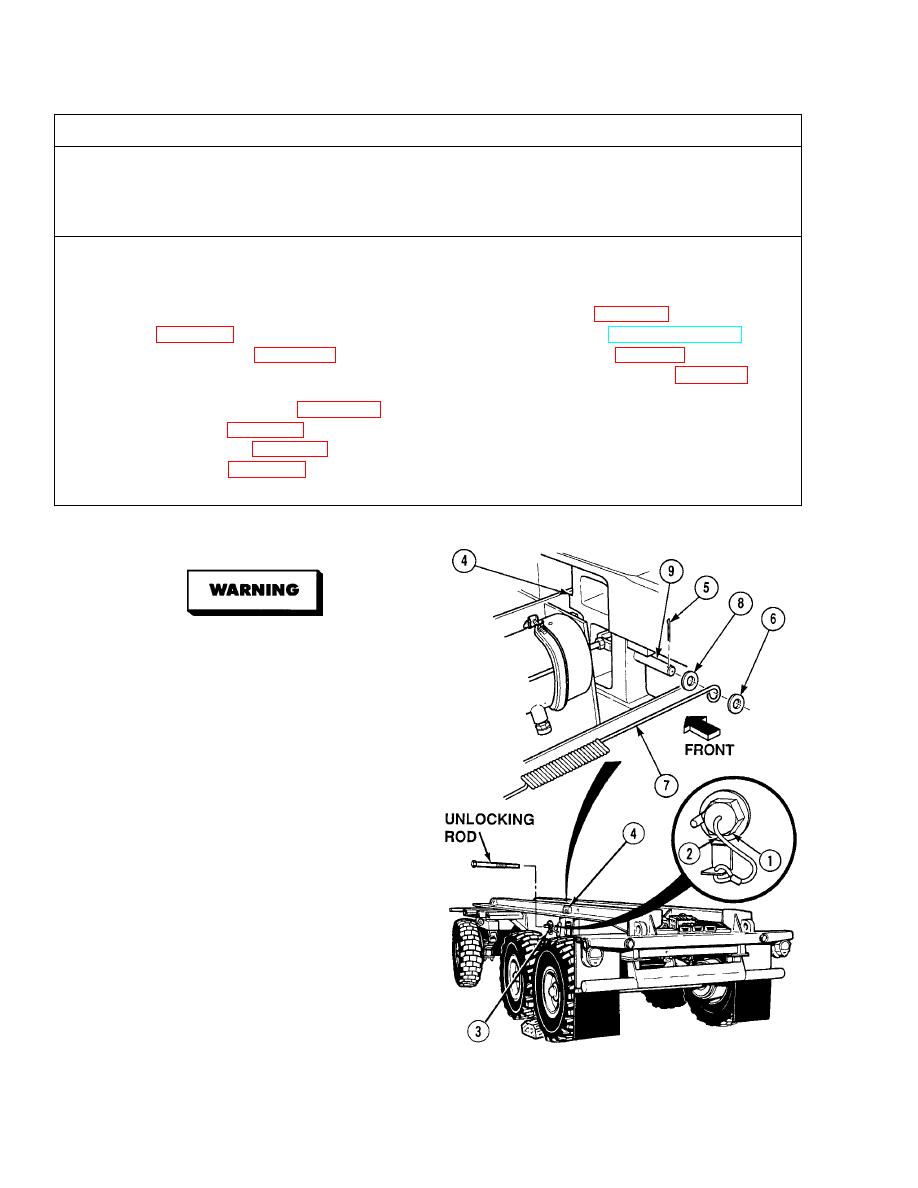

a.

Removal.

Use care when removing springs.

Springs are under tension and can

act as projectiles when released.

Injury to personnel may result.

NOTE

Both flatrack locks are removed

the same way. Right side shown.

(1)

Remove cap (1) on cable (2) from threaded

frame hole (3).

(2)

Install unlocking rod into opposite threaded

frame hole (3) of flatrack load lock (4).

(3)

Turn unlocking rod clockwise until flatrack

load lock (4) is retracted.

(4)

Remove cotter pin (5), washer (6), coil

spring (7) and washer (8) from upper locking

pin (9). Discard cotter pin.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |