|

|||

|

|

|||

|

Page Title:

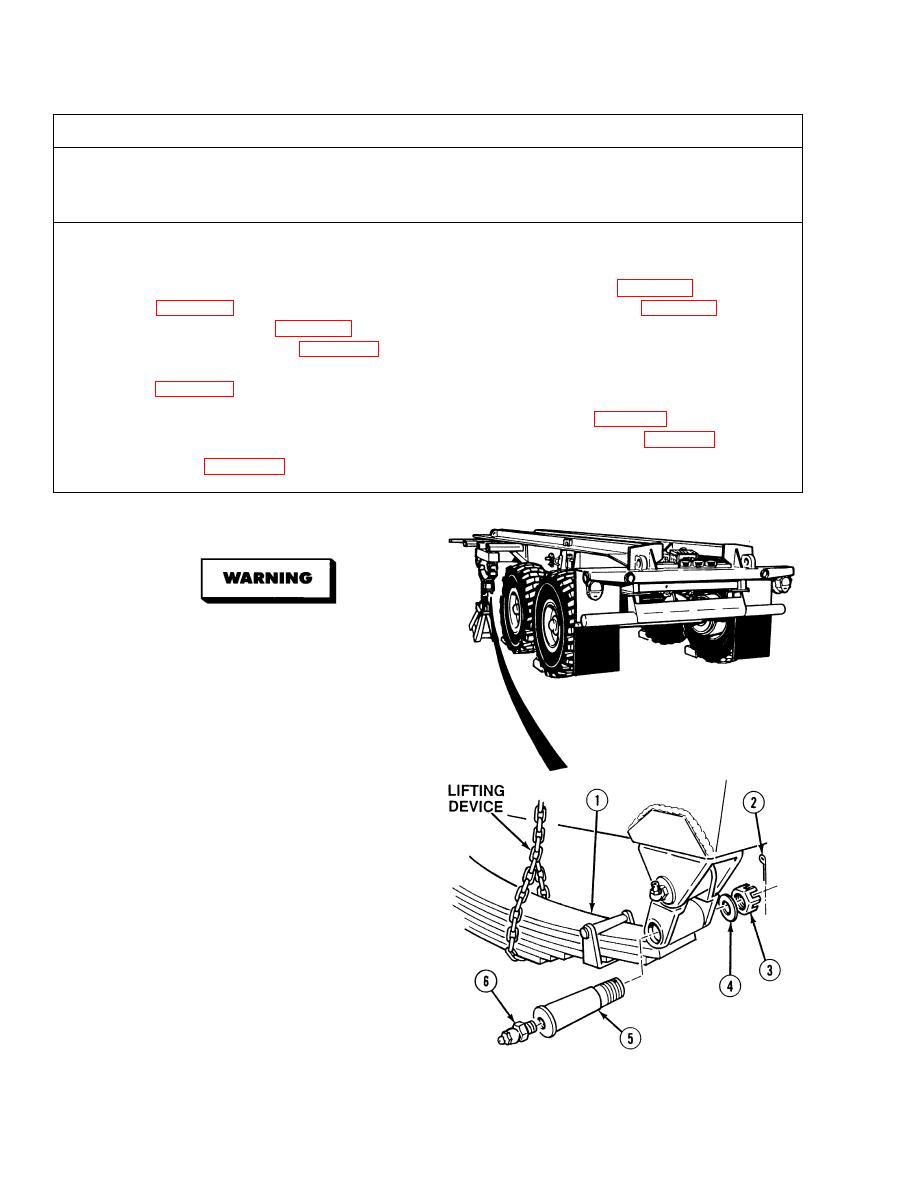

SPRING REPLACEMENT (AXLE NO.1). |

|

||

| ||||||||||

|

|

TM 9-2330-385-14

This task covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Tools and Special Tools

Materials/Parts - Continued

Tool Kit, General Mechanic's

Bushing (2) (Item 3, Appendix I)

(Item 49, Appendix J)

Pin, Cotter (6) (Item 64, Appendix I)

Socket Set, 3/4 in. (Item 39, Appendix J)

Personnel Required

Wrench Set, Crowfoot (Item 58, Appendix J)

Two

(Item 61, Appendix J)

Equipment Condition

Lifting Device Minimum Capacity 270 lb (123 kg)

Wheels chocked, (Para 2-20)

Axle assembly removed, (Para 5-14)

Materials/Parts

Grease (Item 12, Appendix E)

a.

Removal.

Spring weighs 163 lbs

(74 kg). Attach suitable

lifting device prior to

removal to prevent possible

injury to personnel.

Keep hands and fingers out

of spring pin hole or injury

to personnel may result.

(1)

With the aid of an assistant, attach lifting

device to spring (1).

(2)

Remove two cotter pins (2), castle nuts (3),

washers (4) and spring pins (5) from both

ends of spring assembly. Discard cotter pins.

(3)

Lower spring (1).

(4)

Remove lifting device from spring (1).

NOTE

Perform Step (5) if grease

fittings are damaged.

(5)

Remove grease fittings (6) from spring

pins (5). Discard grease fittings.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |