|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-3990-206-14&P

This task covers:

a. Removal

b. Installation

c. Follow-On Maintenance

INITIAL SETUP

Tools and Special Tools

Materials/Parts

Tool Kit, General Mechanic's: Automotive

Adhesive (Item 1, Appendix E)

(Item 15, Appendix I)

Main Rail Cap (a/r) (Appendix G)

Drill, Electric, Portable (Item 3, Appendix I)

Screw, Flooring (a/r) (Item 26, Appendix H)

Drill Set, Twist (Item 4, Appendix I)

Waterproofing, Wood (Item 16, Appendix E)

Gloves, Chemical and Oil Protective

(Item 5, Appendix I)

Equipment Condition

Front and rear wall raised, (Para 7-10)

Goggles, Industrial (Item 6, Appendix I)

Socket, T-30 (Item 13, Appendix I)

a.

Removal.

1

2

3

NOTE

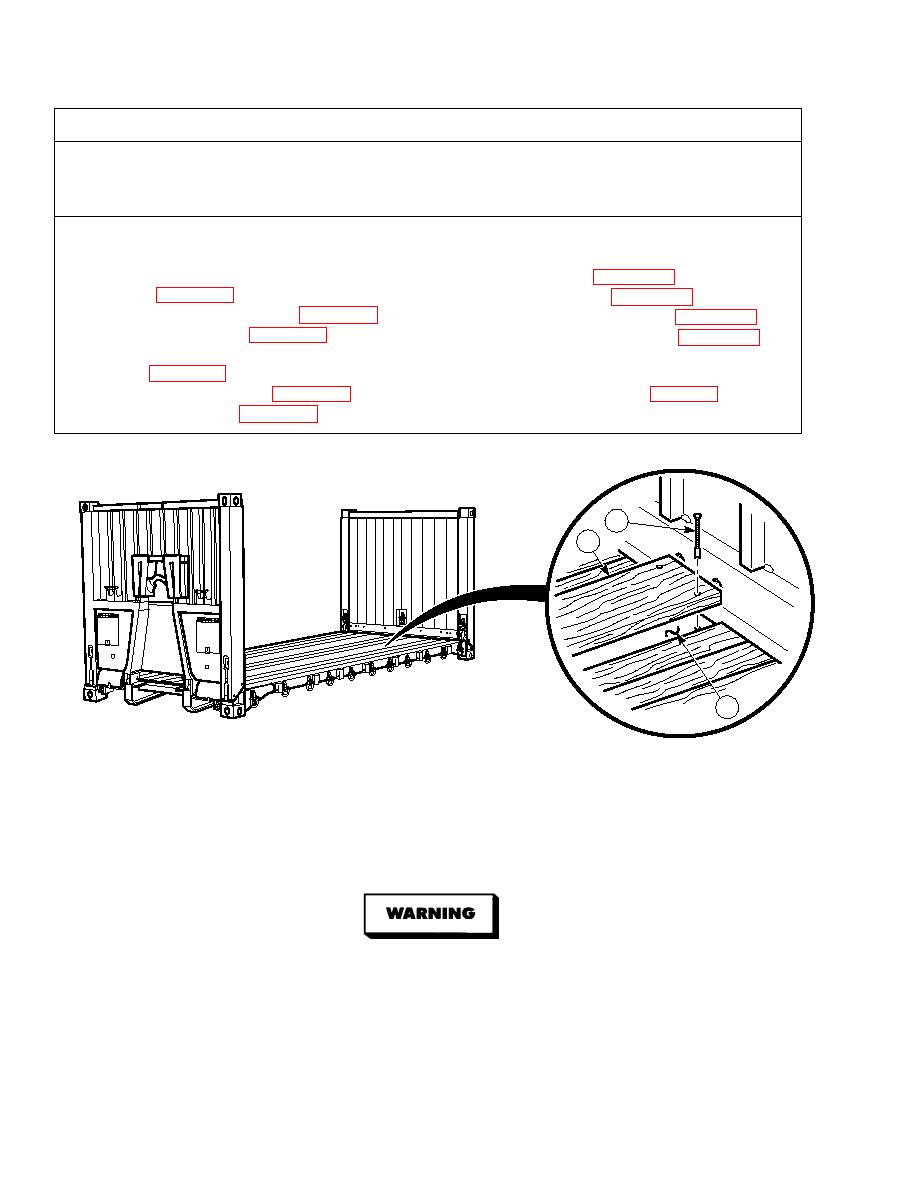

There are six main rail caps on flatrack. All main rail caps are removed the same way.

Number of screws will vary depending on which main rail cap is being removed. The

front and rear main rail caps are installed with 13 screws each. The center main rail caps

are installed with 14 screws.

(1)

Remove and discard screws (1) from main rail cap (2).

Ensure all personnel wear protective gloves when handling main rail caps to protect hands

from wood splinters. Failure to comply may result in injury to personnel.

NOTE

Main rail caps are glued to main rails and will require prying to remove from main rails.

(2)

Remove main rail cap (2) from main rail (3).

(3)

Remove adhesive from main rail (3).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |