TB 9-2320-364-13&P-1

8.

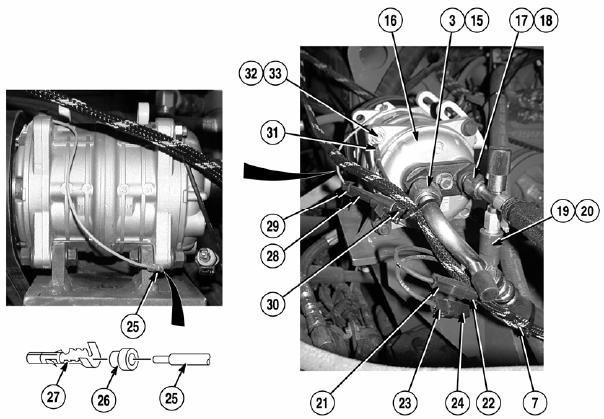

Install preformed packing (15) and hose 2522 (3) on compressor (16). Torque hose 2522 (3) to

18-22 ft-lbs (24-30 Nm).

9.

Install preformed packing (17) and hose 2521 (18) on compressor (16). Torque hose 2521 (18) to

15-18 ft-lbs (20-24 Nm).

10. Install preformed packing (19) and high-pressure switch (20) on hose 2521 (18). Torque high-pressure

switch (20) to 7.5-10 ft-lbs (10-14 Nm).

11. Connect connector (21) of wire harness (7) on connector (22) of high-pressure switch (20).

12. Connect connector (23) of wire harness (7) on connector (24) of high-pressure switch (20).

13. Cut off end of wire (25).

CAUTION

Strip wire after placing it through seal. Failure to comply may result in damage to equipment.

14. Insert 1 in. (25.40 mm) of wire (25) through seal (26).

15. Strip end of wire (25) leaving 1/4 in. (6.4 mm) of bare wire.

16. Insert contact socket (27) in locating hole of terminal crimper using proper hole according to the gage of

wire (25).

17. Slide seal (26) down to end of insulation.

18. Position wire (25) in contact socket (27).

19. Press handles of terminal crimper together until ratchet releases and crimping is complete.

20. Push contact socket (27), seal (26) and wire (25) through connector (28) until seated.

21. Close secondary lock (29) on connector (28).

22. Connect connector (30) of wire harness (7) on connector (28) of compressor (16).

23. Install wire (31) on compressor (16) with screw (32) and nut (33).

0055-24