TM 5-3990-263-13&P

0038

WELDING - Continued

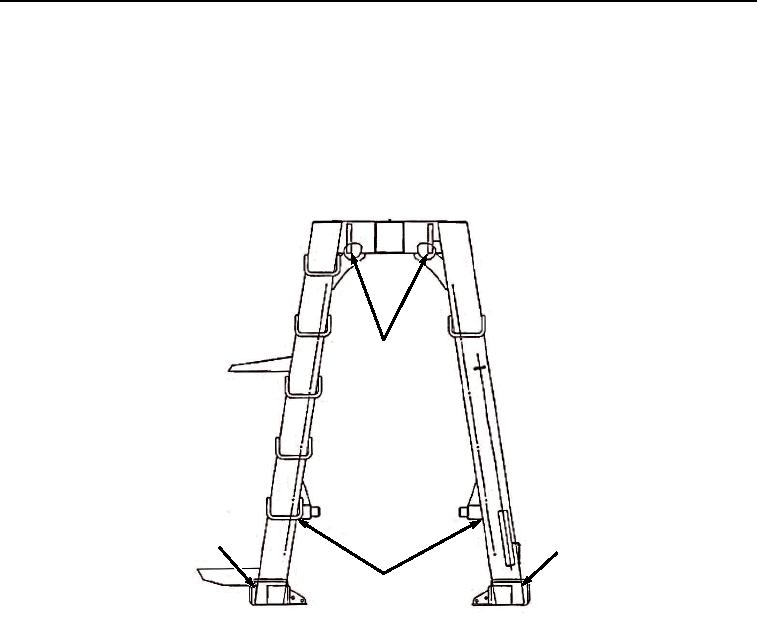

Main Frame Structure

1.

A-Frame to Main Rails (Figure 2, Item 1). These welds are those joining A-frame tubes and main rail tubes to

angled plate between two tubes. Sound welds in these joints are necessary to ensure safe loading and

unloading of loaded BAP. A crack should be repaired before it reaches 1.0 inch (25.4 mm) in length. Combined

length of multiple cracks at either A-frame leg joint should not exceed 2.0 inches (50.8 mm).

3

1

1

2

Figure 2.

A-Frame.

2.

Winch Frame Lower Lock Pin to A-Frame (Figure 2, Item 2). These welds join winch frame lower lock pin outer

circumference to A-frame tubes. Sound welds in these joints are necessary to ensure safe loading and

unloading of loaded BAP. A crack should be repaired before it reaches 0.75 inch (19.0 mm) in length. Combined

length of multiple cracks at either pin joint should not exceed 1.50 inches (38.1 mm).

3.

Winch Frame Upper Pin Saddle Plate to A-Frame (Figure 2, Item 3). These welds join winch frame upper pin

saddle plate to top beam of A-frame. Sound welds in these joints are necessary for safe unloading of loaded

BAP. A crack should be repaired before it reaches 1.5 inches (38.1 mm) in length. Combined length of multiple

cracks at either plate joint should not exceed 3.0 inches (76.2 mm).

4.

Front Lock Outrigger Tubes to Main Rails (Figure 3, Item 1). These welds join front lock outrigger tubes to main

rails. Sound welds in these joints are necessary to ensure safe support of loaded BAP when resting on front

feet. A crack should be repaired before it reaches 1.5 inches (38.1 mm) in length. Combined length of multiple

cracks at either front outrigger tube joint to main rail should not exceed 2.0 inches (50.8 mm).

03/15/2011Rel(1.8)root(maintwp)wpno(M02176)