TM 5-3990-263-13&P

0038

WELDING - Continued

Winch Frame Structure - Continued

6

8

6

6

7

1

5

2

2

4

4

3

3

3

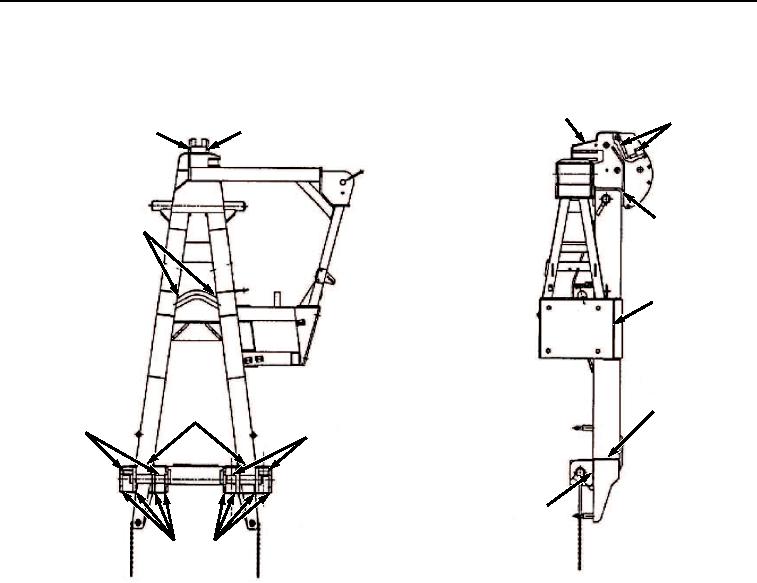

Figure 4. Winch Frame.

2.

Bottom Lock Beam to Side Tubes (Figure 4, Item 2). These welds join the bottom lock beam assembly to side

tubes. Sound welds in these joints are necessary to ensure safe handling of bridge bays and loaded BAP. A

crack should be repaired before it reaches 1.0 inch (25.4 mm) in length. The combined length of multiple cracks

at any joint should not exceed 2.0 inches (50.8 mm).

3.

Bottom Lock Support and Guide Plates to Beam (Figure 4, Item 3). These welds join the eight bottom lock

support and guide plates to the beam. Sound welds in these joints are necessary to ensure safe handling of

bridge bays and loaded BAP. A crack should be repaired before it reaches 1.0 inch (25.4 mm) in length. The

combined length of multiple cracks at any plate joint should not exceed 2.0 inches (50.8 mm).

4.

Bottom Locking Tabs to Pins (Figure 4, Item 4). These welds join locking tabs to bottom lockpins. Sound welds

are necessary to ensure safe handling of bridge bays and loaded BAP. A crack should be repaired before it

reaches 0.25 inch (6.4 mm) in length. The combined length of multiple cracks at any tab joint should not exceed

0.5 inch (12.7 mm).

5.

Winch Mounting Plate to Support Plate (Figure 4, Item 5). These welds join the winch mounting plate to support

plate coming from winch frame side tubes. Sound welds in these joints are necessary to ensure safe handling

of bridge bays. A crack should be repaired before it reaches 1.0 inch (25.4 mm) in length. The combined length

of multiple cracks in this joint should not exceed 2.0 inches (50.8 mm).

6.

Sheave Housing Side Plates to Cap Plate (Figure 4, Item 6). These welds join sheave housing side plates to

top cap plate. Sound welds in cap plate joints are necessary to ensure safe handling of bridge bays. A crack

03/15/2011Rel(1.8)root(maintwp)wpno(M02176)