TM 5-3990-263-13&P

0054

INSTALLATION - Continued

4.

Pre-stress outboard retainer block (Figure 3, Item 6) 1/8 in. (0.3175 cm) to 3/16 in. (0.47625 cm) out of square

off the end of locking pin (Figure 3, Item 1) to counter pull of the weld.

5.

Place a 0.040 in thick shim (Figure 3, Item 5) between end of outboard retainer block (Figure 3, Item 6) and

winch frame (Figure 3, Item 4) and clamp in place.

6.

Pre-heat locking pin (Figure 3, Item 1) to 475F (246C).

7.

Tack weld outboard retainer block (Figure 3, Item 6) on back corners.

8.

Weld root pass on sides of retainer block from back to front.

9.

Build up weld from side to side until just over flush. All weld passes should be made from back to front.

10.

Build up weld across front of retainer block until just under flush.

11.

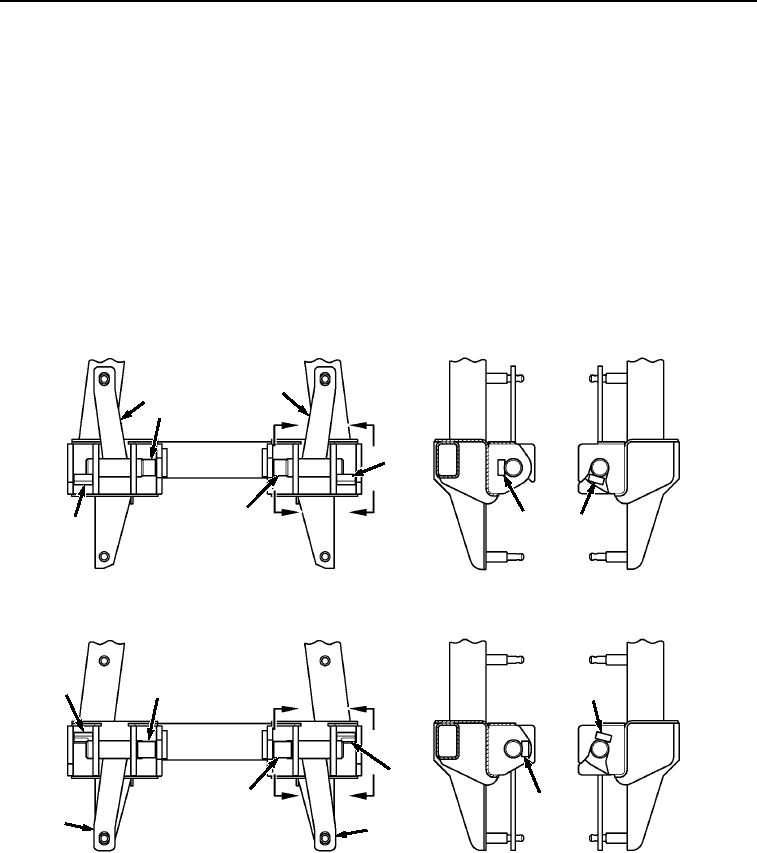

Check that locking levers (Figure 4, Item 2) move freely to upper and lower lock positions. Check that inboard

retainer blocks (Figure 4, Item 3) and outboard retainer blocks (Figure 4, Item 6) are in the correct positions.

2

2

3

A

B

6

3

3

6

6

B

A

UP POSITION

VIEW A

VIEW B

6

3

6

C

D

6

3

3

C

D

2

2

VIEW C

VIEW D

DOWN POSITION

Figure 4. Winch Frame Locking Lever Outboard Retainer Blocks Field Installation.

END OF TASK

END OF WORK PACKAGE

03/15/2011Rel(1.8)root(maintwp)wpno(M04111)